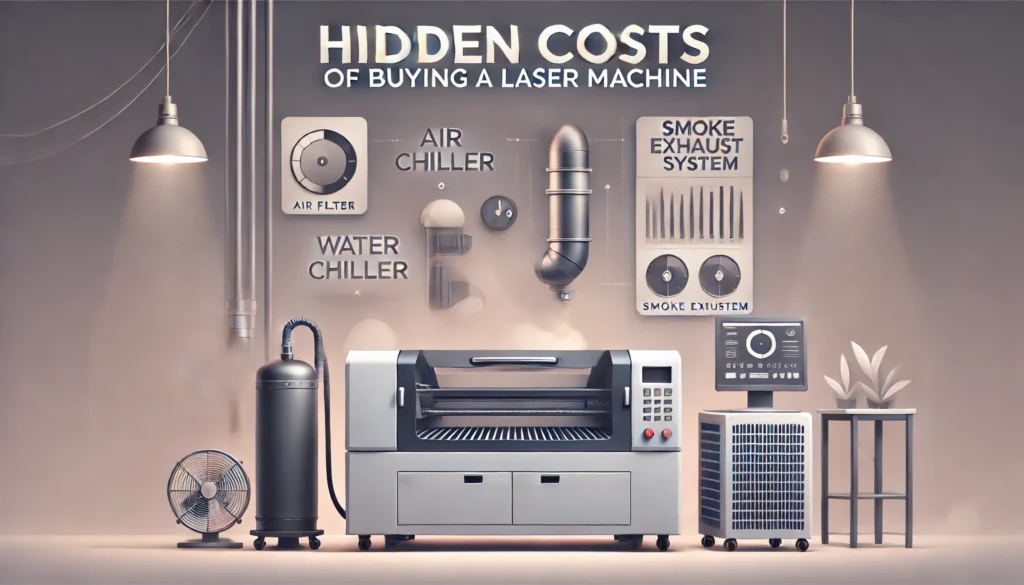

When buying a laser, most people only consider the price of the device itself. Entry-level devices are tempting with prices starting at €150. However, for safe and efficient operation, additional laser costs arise that are often overlooked. To ensure your start into the laser hobby doesn’t become a financial trap, this article outlines the additional expenses you may encounter.

Enclosure for Safe Operation

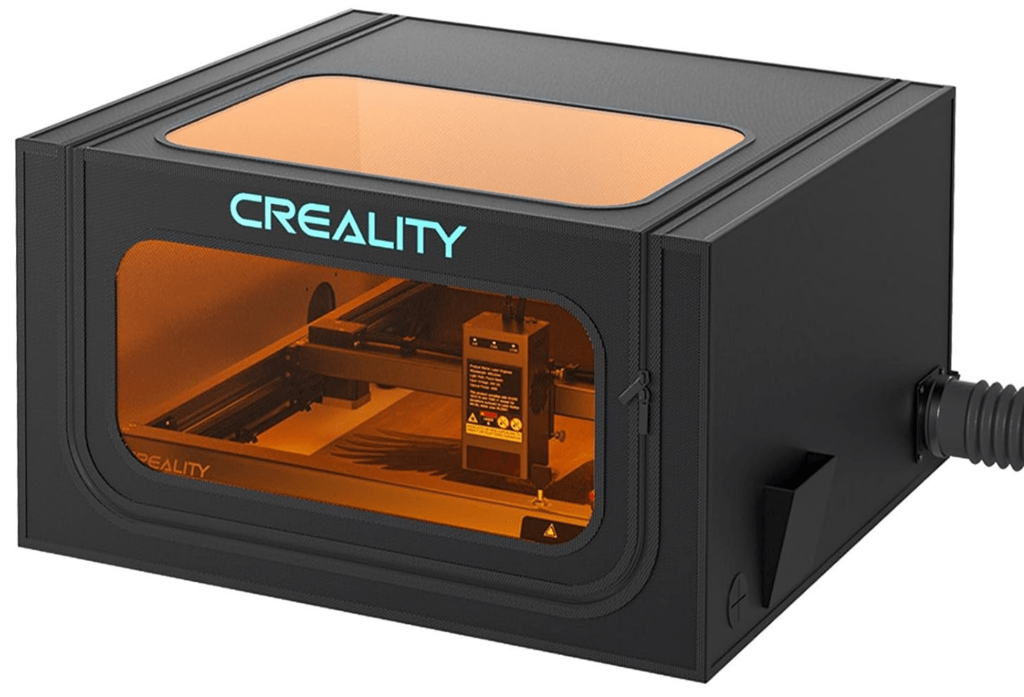

An enclosure is not just an optional accessory but a critical safety measure. It protects you from direct contact with the laser beam and reduces the risk of stray light, which can cause eye injuries. Additionally, an enclosure minimizes the spread of smoke and fumes.

Many high-quality laser devices come with an enclosure, particularly models in the mid- and high-price range. However, inexpensive entry-level devices, also known as “open frame” models, often lack an enclosure. In such cases, you need to purchase or build one separately.

Prefabricated enclosures made of fabric, such as the model from Creality, offer a cost-effective solution. They are lightweight, space-saving, and include integrated connections for an exhaust fan. For even more safety, you can opt for custom or solid enclosures made of metal or wood, which can quickly cost several hundred euros.

If you are skilled in craftsmanship, you can build your own enclosure. With materials like plywood or acrylic sheets, you can create a functional enclosure for about €50 to €100. Ensure that it is both sturdy and well-ventilated. DIY solutions are often cheaper but require time and precise planning.

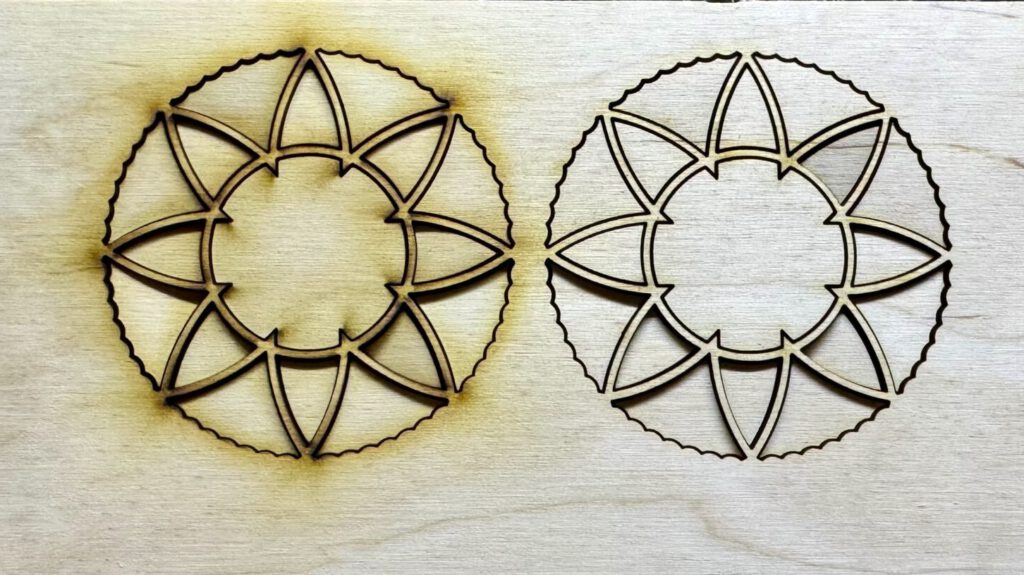

Exhaust Fan and Air Filter

When cutting and engraving with a laser, smoke and unpleasant odors are generated. A powerful exhaust fan is essential to vent these outside. In closed spaces, an air filter is also advisable to remove harmful particles. Although air filter systems are often expensive, the exhaust air should not remain in the living space but ideally be vented outside to maintain air quality. An effective exhaust system can also be built yourself – check out our blog for a detailed guide on DIY exhaust systems. This is a cost-effective alternative to expensive air filters.

AirAssist for Better Cutting Results

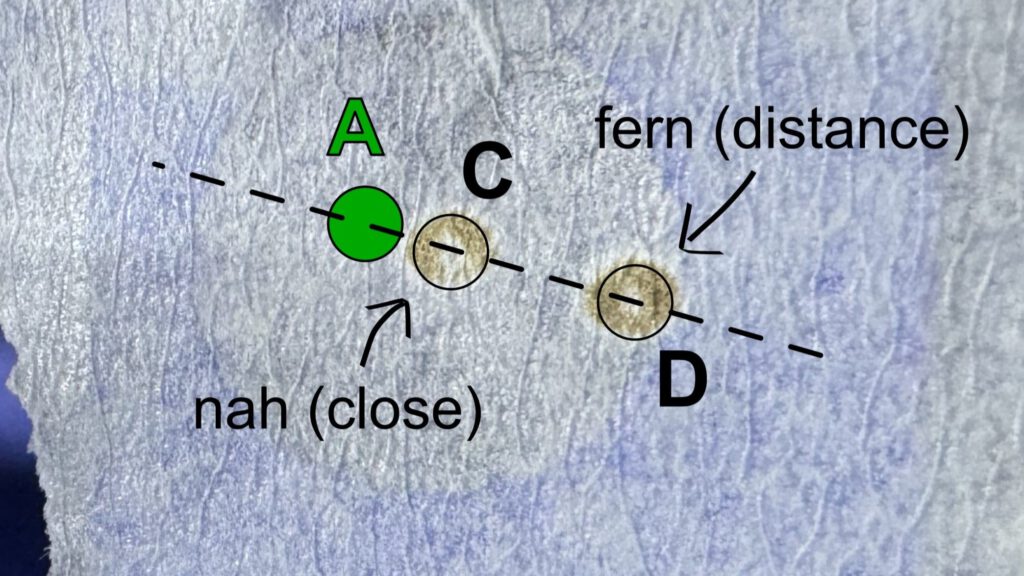

An AirAssist blows air into the cutting zone during operation to keep the lens clean and prevent flames from forming. This ensures clean edges and extends the lifespan of your laser. This accessory is often not included with very inexpensive lasers and adds to the overall laser costs. You should only forego an AirAssist if you exclusively perform engravings.

Water Cooling for CO2 Lasers

CO2 lasers require mandatory cooling to prevent the laser tube from overheating. Most devices come with a simple aquarium pump and a bucket of water, which can suffice for basic cooling. However, if the laser is used in environments with temperatures above 23°C, such as during summer, the cooling unit must actively cool to ensure the performance and lifespan of the laser tube. Those who don’t want to add ice cubes to the cooling water regularly will need a professional water chiller.

Effective cooling is crucial for operation. Without it, the CO2 tube can be destroyed within a short time. In this blog article, you can learn which chiller is best suited for your laser.

Regular Replacement of CO2 Laser Tubes

CO2 laser tubes have a limited lifespan and need to be replaced regularly. The lifespan depends on usage and the quality of the tube, but a replacement can cost several hundred euros. These follow-up costs are often underestimated. In this blog article, I reveal which tube offers the best price-performance ratio.

Other Hidden Costs

In addition to the aforementioned points, there are other laser costs that are easily overlooked:

- Spare Parts and Wear: Lenses and mirrors need occasional cleaning or replacement, especially with intensive use.

- Software: Some lasers require special software that can incur additional licensing fees.

- Material Costs: Depending on the project, material costs for wood, acrylic, or metal can quickly add up.

- Energy Consumption: Laser devices, especially CO2 lasers, have high energy demands, which can impact your electricity bill.

- Tools and Accessories: For example, measuring tools, adhesive tapes, or material holders.

Conclusion

Before buying a laser, you should consider not only the purchase price but also the ongoing laser costs. A detailed look at the necessary additional equipment and maintenance helps you avoid unpleasant surprises. This way, you can budget better and enjoy your laser in the long term.

ADVERTISEMENT: The links marked with an asterisk (*) are affiliate links. If you click on such a link and make a purchase on the destination page, we receive a referral commission from the respective provider or online store. This helps us cover our costs (e.g., web hosting). There are no additional costs or price disadvantages for you when purchasing.