Choosing the right type of laser is one of the most important decisions when entering the world of laser cutting and engraving. Hobbyists, creative individuals, and small businesses often face the question: “Diode vs. CO2 laser?” Fiber lasers are also worth considering. In this article, we compare these three laser types in terms of materials, applications, pros and cons, and costs.

Types of Lasers

Diode Lasers

Diode lasers are especially popular among beginners and DIY enthusiasts. They are excellent for small craft projects, such as engraving wood and cutting paper or cardboard. Due to their low power, they are ideal for delicate work and detailed engraving, such as personalized gifts or models. Another advantage is their ease of use and low maintenance requirements, making them an excellent choice for hobbyists.

Materials:

- Engraving: Wood, plastic, leather, paper, coated metal, glass (with coating)

- Cutting: Thin wood, paper, cardboard, foam

Advantages:

- Affordable (starting at around €150)

- Compact and portable

- Energy-efficient with low power consumption

- Easy to maintain

Disadvantages:

- Limited power, suitable only for thin materials

- Cannot cut transparent acrylic

- Slower cutting compared to CO2 lasers

- Cannot cut or engrave metals (only with special coating)

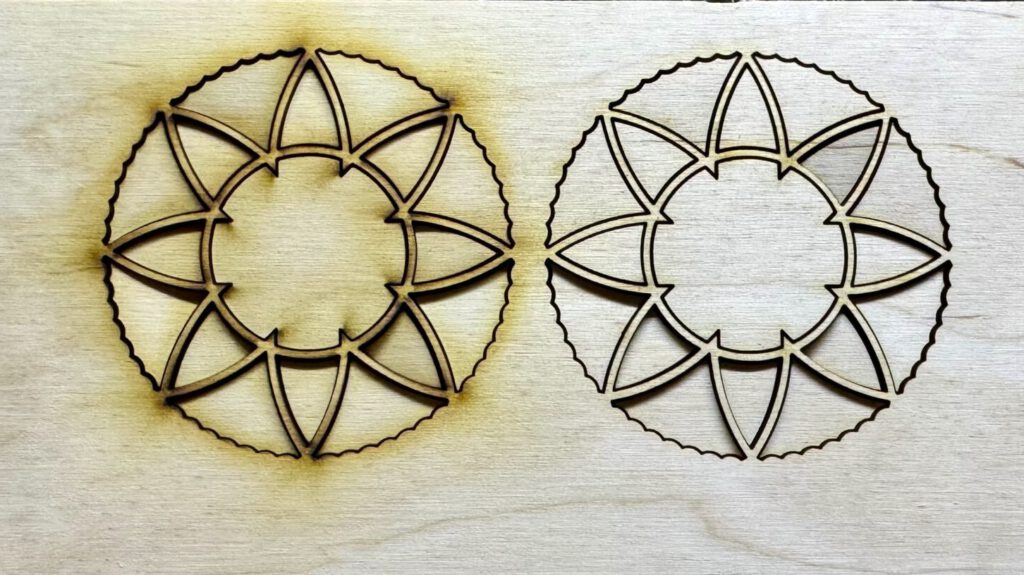

CO2 Lasers

CO2 lasers are mainly used for working with a wide range of materials, especially wood, acrylic, and leather. They are often utilized by small businesses that produce signs, jewelry, or custom decor items. Their versatility also makes them popular in creative workshops as they can both engrave and cut. Another highlight is their ability to process organic materials like glass or stone, making them a preferred choice for artisans.

Materials:

- Engraving: Wood, acrylic, leather, plastic, glass, stone, ceramics

- Cutting: Wood, acrylic, leather, fabrics, paper, cardboard

Advantages:

- Higher power for fast engraving and cutting

- Wide range of materials

- Very precise results

Disadvantages:

- Higher initial cost (starting at around €500 for entry-level models)

- Larger and heavier than diode lasers

- Requires regular maintenance (e.g., cleaning optics)

Fiber Lasers

Fiber lasers are primarily used for metal processing and are designed for industrial applications. They are perfect for engraving metal parts, such as nameplates, tools, or personalized gifts made of stainless steel. Thanks to their speed and precision, they are highly efficient for mass production. Their long lifespan and low maintenance make them attractive for businesses willing to invest in a robust and powerful machine.

Materials:

- Engraving: Metals (stainless steel, aluminum, brass, copper), plastics, coated metals

- Cutting: Very thin metals (depending on power)

Advantages:

- Ideal for metal engraving

- Long-lasting laser source (up to 100,000 hours)

- Very precise and fast

- No maintenance required for the laser source

Disadvantages:

- Very expensive (starting at around €2,000)

- Limited material variety (not suitable for wood or acrylic)

- More complex software for beginners

Comparison Table

| Laser Type | Materials (Engraving) | Materials (Cutting) | Advantages | Disadvantages | Price Range |

|---|---|---|---|---|---|

| Diode Laser | Wood, plastic, leather, painted metal | Wood (thin), paper, cardboard | Affordable, compact, energy-efficient | Limited power, cannot cut transparent acrylic | from €150 |

| CO2 Laser | Wood, acrylic, leather, glass, stone, ceramic | Wood, acrylic, fabrics, cardboard | Versatile, precise, fast results | Requires maintenance, expensive, bulky | from €500 |

| Fiber Laser | Metals, plastics, coated metal | Very thin metal | Ideal for metals, durable, precise | Very expensive, limited for other materials | from €2000 |

Matrix of Materials

The following material matrix provides you with an overview of which materials can be engraved or cut by the various laser types. This will help you to quickly identify the right laser for your projects.

| Material | Diode Laser Engraving | Diode Laser Cutting | CO2 Laser Engraving | CO2 Laser Cutting | Fiber Laser Engraving | Fiber Laser Cutting |

| Wood | ✓ | ✓ | ✓ | ✓ | ✗ | ✗ |

| Acrylic | ✗ | ✗ | ✓ | ✓ | ✗ | ✗ |

| Leather | ✓ | ✓ | ✓ | ✓ | ✗ | ✗ |

| Paper | ✓ | ✓ | ✓ | ✓ | ✗ | ✗ |

| Cardboard | ✓ | ✓ | ✓ | ✓ | ✗ | ✗ |

| Glass | ✓ (with coating) | ✗ | ✓ | ✗ | ✗ | ✗ |

| Stone | ✗ | ✗ | ✓ | ✗ | ✗ | ✗ |

| Metal (coated) | ✓ | ✗ | ✓ | ✗ | ✓ | ✓ |

| Metal (uncoated) | ✗ | ✗ | ✗ | ✗ | ✓ | ✓ |

Conclusion

The choice of the right laser strongly depends on the materials you want to work with and your budget.

- For hobbyists and creative projects, a diode laser is an ideal and affordable entry point.

- A CO2 laser is the best choice if you want to work with various materials and prioritize fast and precise results.

- A fiber laser is perfect if you want to engrave metals and have a higher budget.

No matter which laser you choose, entering the world of laser cutting and engraving offers endless creative possibilities. If you have any questions or need personalized recommendations, let us know in the comments!

ADVERTISEMENT: The links marked with an asterisk (*) are affiliate links. If you click on such a link and make a purchase on the destination page, we receive a referral commission from the respective provider or online store. This helps us cover our costs (e.g., web hosting). There are no additional costs or price disadvantages for you when purchasing.