When it comes to CO₂ lasers, most are shipped with a very basic cooling system: two hoses, a bucket of water, and a pond pump. It doesn’t seem very professional, does it? In this article about laser chiller, I’ll explain why this setup can quickly ruin your laser experience and describe what a proper water cooling system for your laser should look like.

Why Do You Need a Chiller for Your Laser?

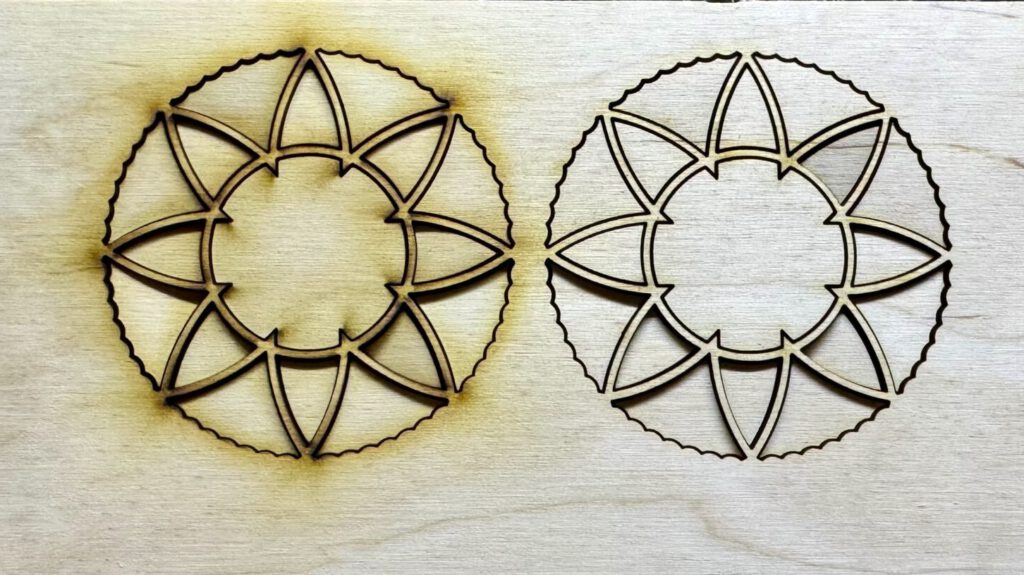

CCO₂ lasers have a photoelectric efficiency of 15% to 20%, meaning that 80% to 85% of the energy is converted into heat. Particularly when cutting at high power levels, the heat generated in the laser tube can quickly cause irreversible damage. Proper heat dissipation is essential to protect the laser tube. If the tube overheats, the gases inside decompose and can no longer regenerate. While this is a normal process in a CO₂ tube, it usually occurs very slowly, allowing for a tube lifespan of 2,000 to 10,000 hours. Excessive heat, however, significantly accelerates this process, reducing the tube’s lifespan to just a few critical hours.

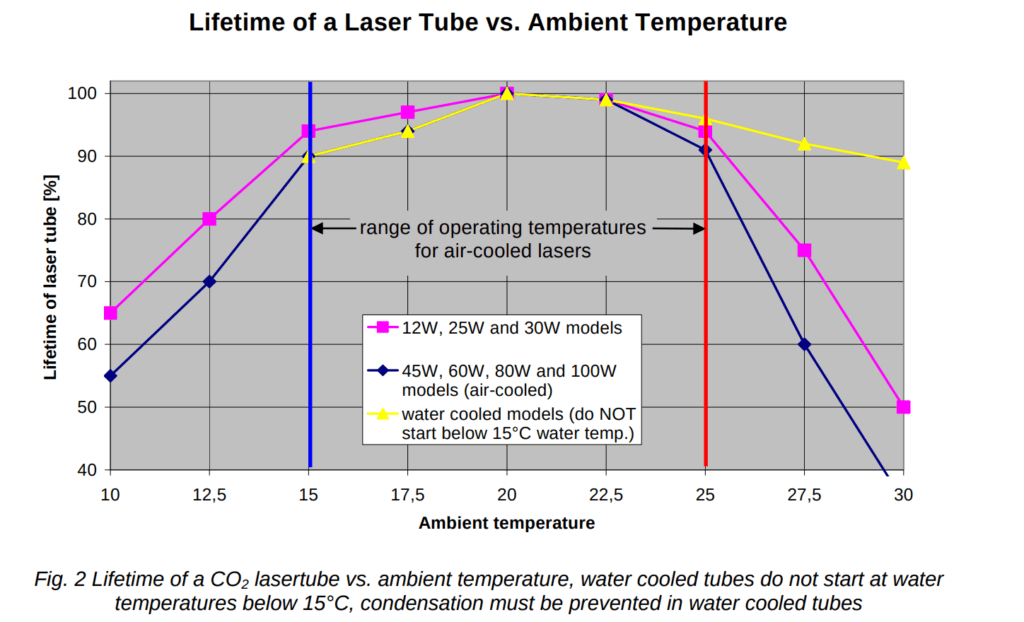

The optimal operating temperature range for a CO₂ laser tube is 15°C to 25°C. Below 15°C, the risk of condensation inside the tube increases, which can cause damage. Above 25°C, chemical processes decompose the gas mixture, drastically shortening the tube’s lifespan.

Recommended Reading: If your workshop temperature falls below 15°C, check out this article: Winter-Proofing Your Laser – Why You Shouldn’t Use Antifreeze.

Proper cooling ensures that you can enjoy your laser for a long time and avoid premature replacement of the tube. Since the tube is the most expensive part of a CO₂ laser, proper care can save years of trouble-free operation.

What Types of Laser Chillers Are Available?

Laser chillers can be divided into two categories: passive water cooling systems and active water cooling systems. They differ primarily in price and cooling performance.

Passive Laser Chiller

Passive chillers consist of a water tank, a pump, and a radiator. They are straightforward and inexpensive, with the most prominent model, the CW-3000*, priced around €150. These chillers are suitable for low-powered lasers in the 40W to 50W range.

Key features: passive cooling via a heat exchanger that dissipates heat into the surrounding air. However, the cooling temperature cannot go below the ambient temperature, which can be problematic in warmer environments. If your workshop exceeds 25°C in summer, the water temperature will also exceed 25°C. In such cases, an active chiller is required.

CW-3000 Passive Chiller

Suitable for:

Advantages

Disadvantages:

Active Laser Chiller

Active chillers include a water reservoir, pump, radiator, and a cooling unit with refrigerant. They function like a refrigerator or air conditioner, quickly cooling the water to the target temperature. Additionally, active chillers allow precise temperature control, independent of the surrounding environment. For lasers with 60W or higher, an active chiller is highly recommended to prevent rapid water heating.

For lasers between 60W and 150W, the CW-5200* is a popular choice. Available from brands like Vevor* and Omtech*, these chillers are priced under €400

CW-5200 Active Chiller

Suitable for:

Advantages:

Disadvantages

Conclusion

Proper cooling is critical to extending the lifespan of your CO₂ laser. Without adequate cooling, overheating can lead to costly damage and the need for tube replacement. While basic setups like water buckets and pond pumps can work temporarily, they are far from professional.

| Feature | CW-3000 (Passive Chiller)* | CW-5200 (Active Chiller)* |

|---|---|---|

| Type | Passive Chiller | Active Chiller |

| Functionality | Heat dissipation via radiator, dependent on ambient temperature | Cooling via refrigerant, independent of ambient temperature |

| Recommended Laser Power | Up to 50W | Up to 150W |

| Operating Conditions | Cool environments (e.g., basement), max 21°C | Warm environments, intensive cutting tasks |

| Ideal For | Engraving, smaller projects | Cutting and engraving, larger projects |

| Price | ~150 € | ~400 € |

| Advantages | Affordable | Precise temperature control, suitable for all CO₂ lasers |

| Disadvantages | Dependent on ambient temperature, limited performance | Higher initial cost |

ADVERTISEMENT: The links marked with an asterisk (*) are affiliate links. If you click on such a link and make a purchase on the destination page, we receive a referral commission from the respective provider or online store. This helps us cover our costs (e.g., web hosting). There are no additional costs or price disadvantages for you when purchasing.

I have heard that we cannot use MilliQ water in the water reservoir.

Deionised or distilled water is best used

Please explain why?

Milli-Q water is too pure for CO₂ laser cooling systems — it aggressively absorbs ions, which can cause corrosion in metal parts. Distilled or deionised water is safer and more stable, making them the better choice for protecting your laser and pump. Some people add a small amount of algaecide or corrosion inhibitor to prevent biological growth and protect metal parts.